Bite Size Work

Within this portfolio section, I've curated impactful yet succinct design projects that may not unfold as full-fledged case studies but nonetheless showcase the prowess of my user experience design skills and their notable business impact. The assortment includes diverse endeavors, from crafting delightful user experiences during my stint as a chocolatier to my technical proficiency in coding and implementing Firebase controls, expanding reach to niche audiences within native mobile apps. These bite-sized glimpses underscore the versatility and effectiveness of my design solutions, each contributing meaningfully to the overall user experience and business objectives.

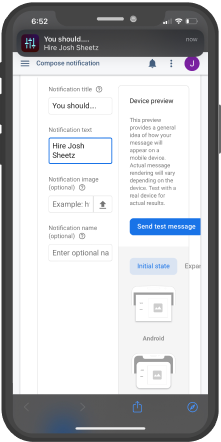

Fire Base Cloud Messaging

In the pursuit of reaching a precisely defined subset of our user base, as a product designer, I embarked on a robust exploration of Firebase—a newly adopted software within our company's tech stack. Following our transition of analytics to Firebase, I delved into its functionalities, particularly its advanced messaging system. Recognizing the potential, I proposed leveraging Firebase for targeted user outreach through push notifications. However, faced with a challenge, as none of our back-end developers were familiar with Firebase, a conventional approach might have halted at this juncture. Undeterred, as a resourceful product designer, I took it upon myself to surmount this obstacle. Confronted with the question of how to efficiently engage a specific user subset for potential testing, I initiated the process of mastering Firebase—a testament to the adaptability and proactive problem-solving inherent in my role.

It’s Going Down Basement

Upon delving into the technical intricacies, I identified a method to cross-reference our analytics data with device IDs to pinpoint users who have demonstrated prolonged app usage. Although unfamiliar with device IDs initially, I rapidly acquired the requisite knowledge to locate and target them. Collaborating with our analytics personnel, I furnished specific parameters for extracting device IDs. Employing the following code in BigQuery, the analytics specialist efficiently retrieved the necessary data:

sqlCopy codebq query “select ‘WITH top_devices(device_id) AS (VALUES ‘ || string_agg( ‘(\” || device_id || ‘\’)’, ‘, ‘) || ‘) select device_id, registration_token from devices where device_id in (select device_id from top_devices)’ from (select device_id, count(distinct date(event_time)) as days_used, date(min(event_time)) as min_date, date(max(event_time)) as max_date from...

Once armed with the requisite device IDs, the next step involved creating a targeted "topic" in Firebase to streamline user communication. Seeking assistance from a fellow developer, I shared the code, leading to the creation of the following "topic":

pythonCopy codetopic_name = f'{key}%{value}'

This enhancement empowers us to dispatch precise push notifications, facilitating tailored communication strategies for testing, promotions, offers, and new feature releases.

Metamorphosis

Just Call Me Willy Wonka

Our project focused on the avant-garde creation of chocolates through 3D renders meticulously crafted in Rhino. The genesis of our shapes and textures drew inspiration from nature, particularly the dynamic transformations found in changing landscapes—thus, the embodiment of chocolate metamorphosis. Our objective was to transcend conventional production methods and explore the boundless possibilities enabled by emerging technologies. In the face of these advancements, adaptation and innovation became paramount, challenging established and, at times, antiquated approaches to creation. This endeavor underscored the convergence of design and 3D printing, seamlessly applied to a culinary domain where traditional methodologies have long held sway, despite our limited culinary expertise.

The Process

-

Draft

Commencing our chocolate venture, we initiated the design process in Rhino—a precision drafting software renowned for creating intricate 3D objects. Each team member undertook the creation of three distinct models. My contributions included the design of a plain half dome, a full spike, and a budding square version. A significant portion of our project timeline was dedicated to ensuring that our renders were watertight and conducive to mold production. While we initially worked with 2-inch models, our decision to transition to 1-inch models stemmed from insights gathered during user testing. This adjustment proved instrumental in optimizing the chocolate consumption experience, allowing users to sample all five shapes with greater ease.

-

Print

With our renders completed in the drafting software, the next phase involved 3D printing, utilizing two distinct printers. Through thorough experimentation, we determined that the Ultimaker yielded the optimal resolution to achieve our desired outcomes. The process, however, was not without challenges, as we encountered various issues with renders and printing. Iterating through multiple cycles of rendering and printing, we successfully produced five high-quality 3D prints.

-

Mold

The molding process involved meticulous craftsmanship, utilizing plastic curing boxes and food-safe silicone for each mold. Constructing individual curing boxes from a plastic presentation board, we securely positioned the 3D prints within their designated containers. Subsequently, we meticulously poured food-safe silicone into the molds. Following a curing period of approximately 24 hours, the molds were primed and ready for the chocolate infusion phase.

-

Enjoy

The culmination of this venture found its zenith in the meticulous process of taste testing and chocolate pouring. Although methodical and deliberate, the process yielded gratifying results. Employing an array of chocolates and flavors intricately inspired by the unique shapes and landscapes, we embarked on a nuanced journey of chocolate production. Given the limitations of each mold, capable of producing only four pieces at a time, our approach to mass production demanded a measured cadence. After each pour, the molds were promptly placed in the freezer for a five-minute interval, followed by a meticulous rinse, and the process meticulously repeated.